Are you looking for a reliable and efficient Winch Type Lift? Do you need to enhance the movement of heavy loads while ensuring smooth and safe operation? You’ve come to the right place. Our company specializes in high-performance Winch Type Lifts, designed for durability, strength, and efficiency, making them ideal for a variety of industrial and commercial applications.

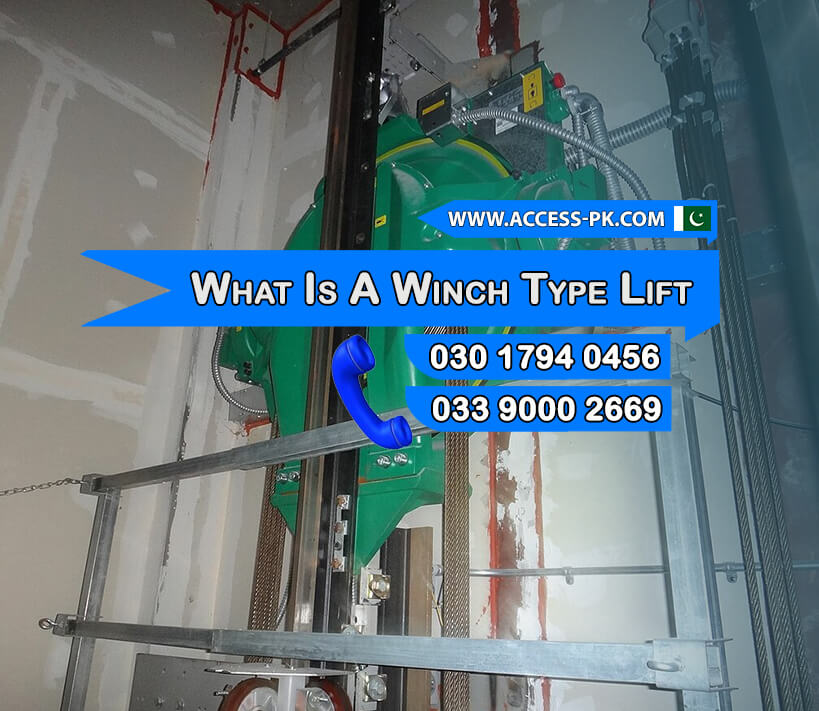

A winch type lift is a highly effective solution for lifting heavy loads in various industrial settings. It uses a winch mechanism, typically powered by electric or hydraulic motors, to raise or lower goods with ease. This system provides a reliable method for transporting items vertically, especially when space constraints or weight distribution issues are a concern. Access Technologies, owned by Imran Rafi, specializes in providing top-quality winch type lifts tailored to meet specific requirements. With its simple design and powerful operation, the winch type lift ensures efficiency and safety during heavy lifting tasks.

The operation of a winch type lift is straightforward yet highly efficient. The system relies on a winch that pulls a cable or rope attached to the load, allowing it to be raised or lowered with precision. Typically, the winch is controlled by a motor, which can either be manual or automated. As the winch rotates, it winds or unwinds the cable, which is then connected to the lifting platform. Additionally, winch type lifts are designed to offer smooth motion, reducing the risk of abrupt movements or damage to the load. This makes them a dependable choice for various lifting applications.

Winch type lifts find widespread use in industries where heavy lifting is essential. They are commonly used in warehouses, construction sites, and shipping ports for lifting and moving goods efficiently. For example, in construction, winch type lifts help transport materials like steel beams or concrete blocks to higher levels. Furthermore, these lifts are versatile and can be used to lift bulky items in narrow or confined spaces. With their reliable operation and ability to handle significant loads, winch type lifts are invaluable tools in enhancing productivity and safety in various operational environments.

Get Free Quotes

A winch type lift is a versatile and efficient lifting system designed to handle heavy loads in various environments. It uses a winch mechanism, often powered by an electric or hydraulic motor, to raise and lower goods with precision and safety. The winch type lift is typically composed of a winch drum, cable, pulley, and lifting platform. As the winch rotates, it winds or unwinds the cable, lifting or lowering the load as needed. This type of lift is especially useful in industries where space is limited or the load needs to be moved vertically over long distances. The simplicity and reliability of a winch type lift make it an ideal choice for applications in construction, warehouses, and industrial facilities.

A winch type lift provides powerful vertical lifting, ideal for industrial and commercial use. It operates with a winch connected to a cable or rope to move heavy loads. The winch is powered by electricity or hydraulics, offering steady control. The lift’s simplicity and versatility are key benefits. It fits in limited spaces and handles significant weight, making it efficient for material transport. Winch lifts are commonly used in construction, warehouse, and shipping industries to move concrete, steel, or heavy equipment. The design ensures smooth lifting and safe lowering of loads.

Winch type lifts operate through a simple yet effective mechanism. At the core of the system is the winch drum, which holds the lifting cable or rope. The winch is powered by either an electric or hydraulic motor, which turns the drum, causing the cable to either wind or unwind. The cable is attached to a load-bearing platform, and as the cable moves, it raises or lowers the load accordingly. The lift’s operation is typically controlled by a user-friendly control panel that allows operators to adjust the speed and direction of the lift. Additionally, winch type lifts often include safety features such as overload protection and emergency stop buttons to prevent accidents.

Winch type lifts are widely used across different industries, providing an essential service for transporting heavy and bulky items in confined or vertical spaces. In the construction industry, they are often used to lift materials such as steel beams, concrete blocks, and heavy machinery to elevated levels. These lifts are especially valuable on construction sites with limited space, where other types of lifts may not be feasible. Additionally, winch type lifts are commonly found in warehouses, where they are used to move large pallets of goods between floors. They are also used in shipping ports to load and unload cargo efficiently. The versatility of winch type lifts allows them to be adapted to a wide range of industries, including mining, manufacturing, and logistics. Their reliability and capacity to handle heavy loads make them an invaluable tool in any operation where vertical transportation is required.

Get Free Quotes

A winch type lift offers significant advantages for heavy-duty applications, particularly when it comes to lifting and transporting large loads. One of the main benefits is its ability to handle heavyweights with ease. Unlike other lifting systems, the winch type lift relies on a winch mechanism, which provides a controlled and steady force, making it ideal for moving bulky materials like steel beams, heavy machinery, or large pallets of goods. This makes it perfect for industries like construction, warehousing, and manufacturing. Additionally, winch type lifts are built to endure tough conditions, offering durability and reliability even in harsh environments. The use of a winch mechanism allows for smooth lifting and lowering of materials, minimizing the risk of damage to both the goods being lifted and the lifting equipment itself.

Moreover, winch type lifts are versatile and adaptable, making them suitable for a wide range of heavy-duty applications. Their design allows them to operate in tight or confined spaces where other lifting equipment may not fit. This flexibility is especially valuable in environments such as construction sites with limited room for large machinery. Additionally, winch type lifts can be customized to suit the specific needs of different industries. They come in a variety of sizes and weight capacities, making it possible for businesses to choose the right model that matches their unique lifting requirements. This level of customization enhances their utility, as businesses can get exactly what they need without having to invest in costly, specialized equipment.

Get Free Quotes

Choosing the right winch type lift for your business needs is crucial to maximizing efficiency and ensuring safety in your operations. The first step is to assess the lifting capacity required for your specific tasks. Winch type lifts come in various weight capacities, so it’s important to match the lift’s capabilities with the size and weight of the materials you intend to lift. Consider the average load weight and peak lifting demands to ensure the lift will handle the job without overloading. Additionally, the height and distance the lift needs to operate within should be considered. Some lifts are designed for shorter vertical distances, while others are built for high-rise applications. By evaluating your operational needs, you can select a winch type lift that will optimize performance and reduce the risk of mechanical failures due to overuse or misuse.

Another factor to consider when choosing the right winch type lift is the environment in which it will be used. Winch type lifts are available in both indoor and outdoor models, with certain features tailored for specific environments. For example, outdoor lifts may be designed with weather-resistant materials, while indoor models may offer a more compact design for use in confined spaces. You should also consider safety features such as overload protection, emergency stop buttons, and automatic braking systems. These features will help prevent accidents and ensure smooth operation in high-risk environments. Additionally, the maintenance requirements of the winch type lift should be taken into account. Lifts with a simple design and durable components tend to have lower maintenance needs, offering a cost-effective long-term solution. By carefully evaluating these factors, businesses can make an informed decision when selecting the right winch type lift for their operations.

Get Free Quotes

Maintaining a winch type lift is crucial to ensure its longevity, efficiency, and safety during operation. Regular maintenance helps prevent mechanical failures and costly repairs, keeping the lift in optimal working condition. It’s essential to perform routine checks on the winch’s motor, cable, pulley system, and overall structure. Regularly inspect the cables for signs of wear, fraying, or corrosion, and replace them if needed to prevent accidents. The winch type lift’s lubrication system should also be monitored and maintained to reduce friction and ensure smooth operation. Check the winch’s hydraulic or electric system for leaks or faults to ensure effective power. Regular maintenance helps prevent downtime and improves the winch lift’s efficiency over time.

To ensure a winch type lift operates smoothly, routine maintenance is key. Start by checking the winch cable for signs of wear or damage, as frayed cables can compromise safety and efficiency. If any damage is found, replace the cable immediately to prevent it from snapping during use. Regularly lubricate the moving parts of the winch system to reduce friction and prevent unnecessary wear on components. Additionally, inspect the motor and control system for any signs of malfunction, and perform any necessary repairs. Ensure that all fasteners and bolts are tight to prevent vibrations and potential safety hazards. Finally, keep the area around the winch type lift clear of debris and ensure the lift’s housing is clean and free of obstructions. Scheduling regular inspections and maintenance checks will help you extend the life of the lift and keep operations running smoothly.

Operating a winch type lift requires strict adherence to safety measures to protect both operators and the equipment. Operators should receive proper training on safely operating the lift, including understanding its control mechanisms and weight capacity. Always check the load’s weight to ensure it does not exceed the lift’s rated capacity. Overloading can damage the system or cause accidents. Additionally, before using the winch type lift, conduct a thorough pre-operation inspection to ensure all components are in working order. Operators should also be aware of the lift’s emergency stop functions and know how to quickly respond in case of an emergency.

Troubleshooting common issues with a winch type lift is essential to prevent unexpected downtime and costly repairs. One common issue is a malfunctioning winch motor, which may not provide enough power to lift the load. If this occurs, first check the power source to ensure the motor is receiving sufficient voltage. If the motor still doesn’t function properly, it may need repairs or replacement. Another common problem is the cable becoming tangled or worn, which can lead to improper lifting or even cable failure. Regularly inspecting and replacing the cable can prevent this issue. If the winch type lift is experiencing difficulty lifting the load, it may indicate a problem with the hydraulic or electric system.

Get Free Quotes